The 5-axis sliding beam gantry machine series is based on sliding beam gantry machine, improves high-speed performance, equipped with A, C double pendulum milling head, to achieve five-axis attachment machining. It is suitable for high-precision and high-speed processing of complex workpieces with three-dimensional profiles, widely used in aerospace shaped parts, ships, railway locomotives, steam turbines, moulds and other industries, suitable for processing ferrous metals as well as non-ferrous metals.

The 5-axis sliding beam gantry machine series is based on sliding beam gantry machine, improves high-speed performance, equipped with A, C double pendulum milling head, to achieve five-axis attachment machining. It is suitable for high-precision and high-speed processing of complex workpieces with three-dimensional profiles, widely used in aerospace shaped parts, ships, railway locomotives, steam turbines, moulds and other industries, suitable for processing ferrous metals as well as non-ferrous metals.

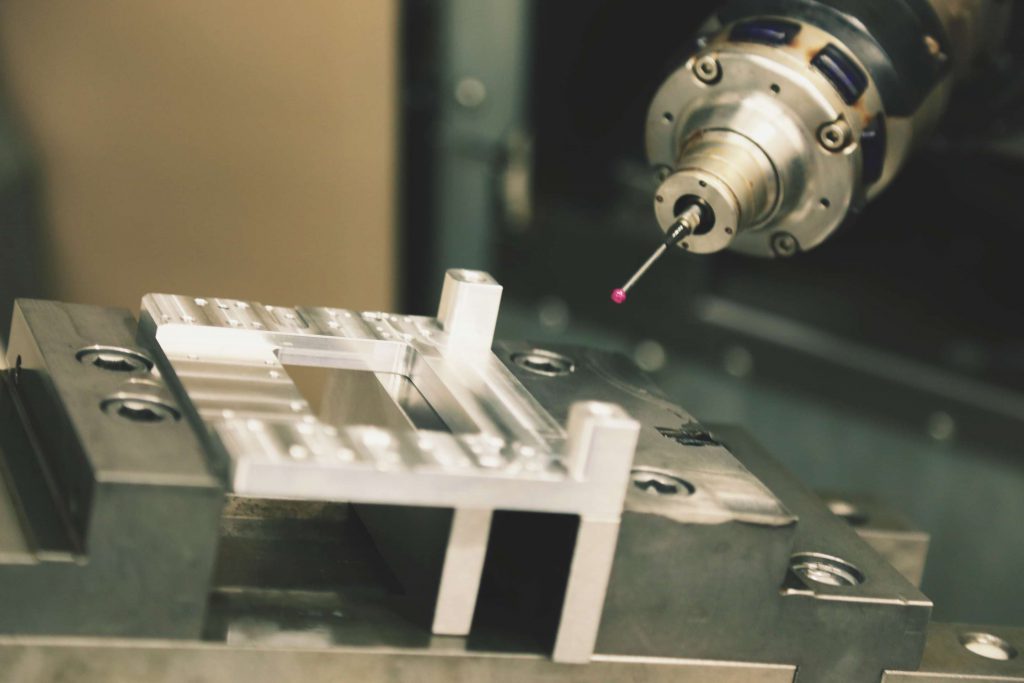

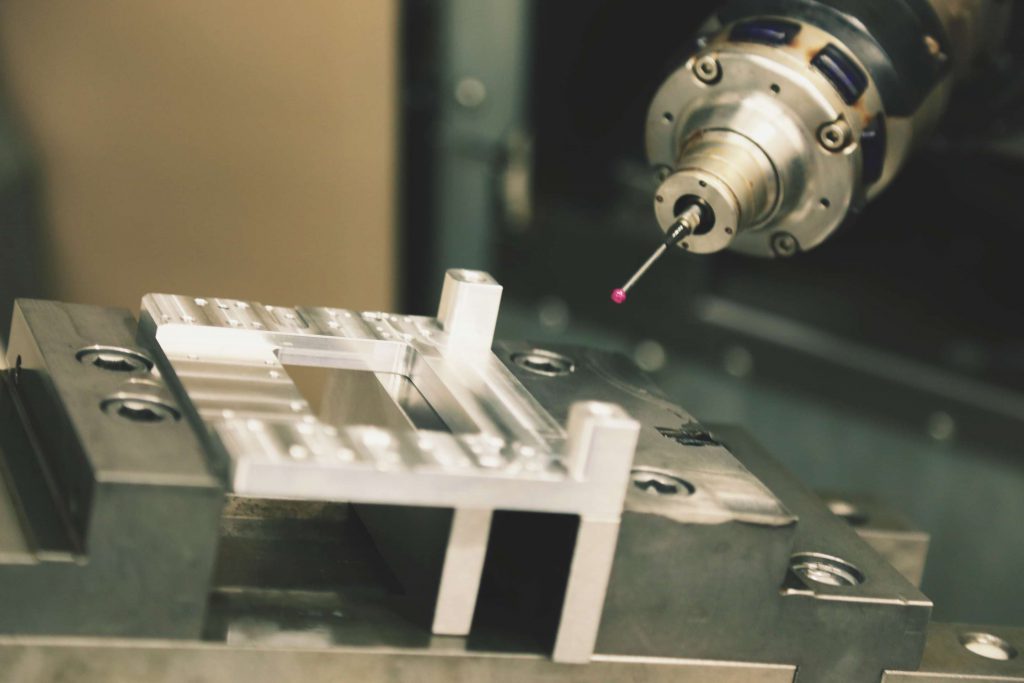

Machining centers of this series can continuously perform milling, drilling, stretching, deployment and other processes. It is suitable for processing all kinds of parts with high precision, multiple processes and complex molds, such as all kinds of boxes, presses, cams, plate samples, aircraft parts, internal combustion engine parts, etc. d. It is an automated machine to improve work efficiency.

| Specifications KVC650M KVC650MA | Kvc650n kvc650na | |||||

| Table characteristics | Table size(Width×Length) | mm | 460×1000 | 460×1000 | ||

| T-slots(Number of slots - width x pitch) | mm | 5-18×80 | 5-18×80 | |||

| Max. table load | kg | 700 | 700 | |||

| Relocation | X/Y/Z | mm | 650(On request)/500/600 | 650(On request)/500/600 | ||

| Spindle | Spindle drive power (fast / 15 min) | kW | 7.5/11 | 7.5/11 | ||

| Spindle cone | BT40 | BT40 | ||||

| spindle speed | rpm | 20-8000 | 20-8000 | |||

| Submissions | Working feed rate(X、Y、Z) | mm/min | 1-10000 | 5-10000 | ||

| Accelerated feed(X、Y/Z) | mm/min | 24000/20000 | 20000 | |||

| Tool system | Capacity of the tool magazine | piece | 16 | 16 | ||

| Max. tool diameter | mm | φ105 | φ78 | φ105 | φ78 | |

| Max. tool diameter (with free adjacent cell) | mm | φ160 | φ130 | φ160 | φ130 | |

| Max. length of tool | mm | 250 | 300 | 250 | 300 | |

| Max. Weight of the tool | kg | 6 | 8 | 6 | 8 | |

| Accuracy (ISO) | Positioning | mm | 0.006 | 0.009 | ||

| Repeatability | mm | 0.005 | 0.007 | |||

| Machine weight | kg | 5500 | ||||

| CNC system | 发那科、西门子、三菱 | |||||

Sichuan Changzheng Machine Tool Group Co., Ltd.