The 5-axis sliding beam gantry machine series is based on sliding beam gantry machine, improves high-speed performance, equipped with A, C double pendulum milling head, to achieve five-axis attachment machining. It is suitable for high-precision and high-speed processing of complex workpieces with three-dimensional profiles, widely used in aerospace shaped parts, ships, railway locomotives, steam turbines, moulds and other industries, suitable for processing ferrous metals as well as non-ferrous metals.

The 5-axis sliding beam gantry machine series is based on sliding beam gantry machine, improves high-speed performance, equipped with A, C double pendulum milling head, to achieve five-axis attachment machining. It is suitable for high-precision and high-speed processing of complex workpieces with three-dimensional profiles, widely used in aerospace shaped parts, ships, railway locomotives, steam turbines, moulds and other industries, suitable for processing ferrous metals as well as non-ferrous metals.

Technical specifications

Milling and Turning Machining Center DMC1000 — is a new machine for processing components with advanced technologies combining the most modern machines. The machine is characterized by high accuracy, high capacity, high rigidity and ease of execution of complex processing. This machine is suitable for processing: ship and automotive crankshafts, generator rotors, printing machine cylinders, aircraft chassis, railway conveyor rollers, steam turbines due to high precision. Complex shape and large amount of processing. Traditional processing methods are difficult to meet the demand for large and medium-sized parts.

Milling function

The milling spindle of the machine is equipped with a powerful and high-speed electric spindle, which has a powerful milling function. Mouse disc unloading device can protect the precision of the milling spindle, extend the service life, and ensure the turning of large cutting volume.

Central frame structure

The machine has advanced and efficient central frame structure, self-centering, hydraulic clamping, stable and reliable structure. It can realize auxiliary workpiece loading with high accuracy and flexibility.

Spindel

The main spindle of the machine tool uses a mechanical spindle that is powerful enough to provide a reliable guarantee for processing large and medium parts.

The B axis of the machine has good rigidity and high positioning accuracy. It can continuously index and participate in interpolation to achieve machine communication; It can also automatically index and perform processing at a fixed angle after positioning the mouse disc.

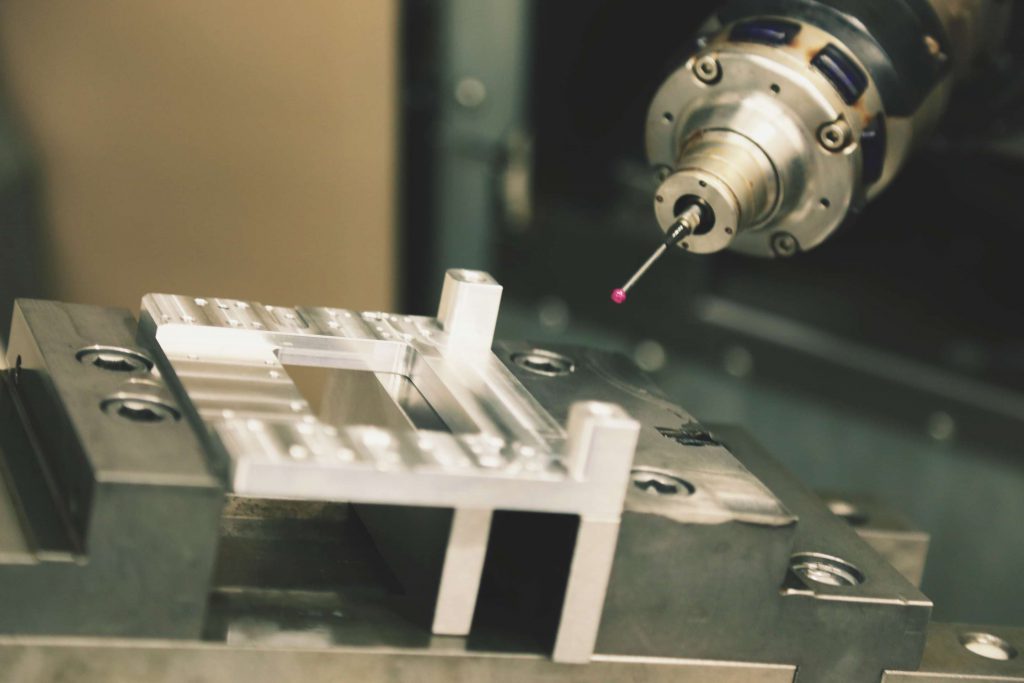

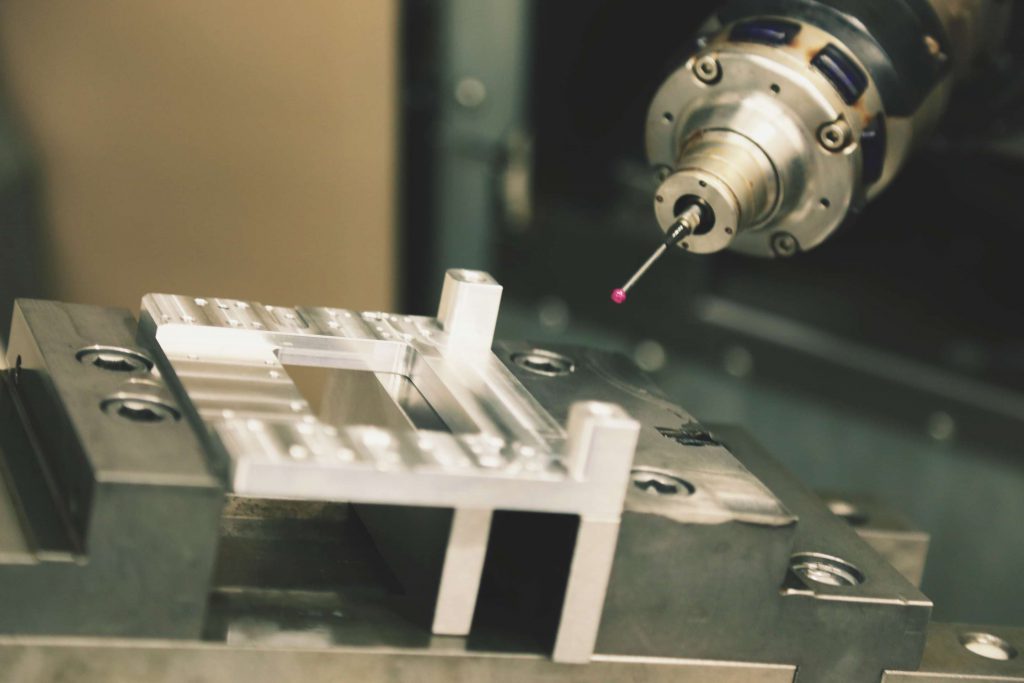

Detection system

The machine adopts full closed cycle control. Thanks to the tool detection, it can detect and correct the accuracy changes caused by the tool in time. Real-time workpiece inspection can be implemented on the machine, which makes inspection simple and convenient, and also avoids secondary loading in case of unqualified processing.

| Technical specifications | 1000德国马克 | DMC1500 | |

| Diameter of the turn of the chair | mm | φ1016 | φ1620 |

| Distance from spindle face to table surface | mm | 5000 (On request 6500/8000) |

5000 (On request 6500/8000) |

| Twisting moment | kW | 37 or 55 | 55 |

| Spindle drive power (post / 30 min) | kW | 18.5/22(FANUC) 28/36(西门子) |

|

Sichuan Changzheng Machine Tool Group Co., Ltd.